PILOT PLANT DESIGN & SCALE UP TO COMMERCIAL SCALE PRODUCTION

REDUCE YOUR RISK BY SPENDING LESS IN A PILOT PLANT DESIGN TO GET THE PROCESS AND PRODUCT RIGHT BEFORE EMBARKING ON LARGE SCALE PRODUCTION ( PILOT PLANT SCALE UP ).

APART FROM ESTABLISHING THE PRODUCT QUALITY FOR TEST MARKETING AND ACCEPTANCE, A WELL PILOT PLANT DESIGN GIVES THE BENEFIT OF OPTIMISING THE PROCESS AND EQUIPMENT TO MINIMISE COST OF PRODUCTION.

Pilot Plan

Chemical Process Engineers principally recommends going through the step of Plant to proof the process on a small scale, irrespective of the source of technology.

This helps the investor in assessing the technology on a smaller scale at a lower investment thus minimizing the risk due to unforeseen uncertainty with respect to product yield, product quality, process losses, precise utility requirement, etc. This apart, going through the Pilot Plant scale up stage helps in test-marketing of the product(s) and getting positive response from the potential customers. All necessary data should be collected during operation of the Plant, which then serves as the basis for design of large scale production plant.Learn the process how we conduct the mass balance and energy balance in the chemical process engineering firm with the experts.

ADVANTAGES WITH PILOT PLANT SCALE UP APPROACH:

Setting up a Plant also involves complete process engineering, detailed engineering and careful execution.

• Spend less and get the process and product right before embarking on full scale

• Establish balancing of multiple unit processes & unit operations involved in a production line to ensure 100 % utilization of equipment capacity.

• Tweak with production process in the plant to minimize batch time which can ensure maximum capacity utilization.

• Establish the right type of solid-liquid filtration equipment; mixing equipment, reaction equipment, evaporation equipment, drying equipment, etc.

• Establish process control logic in the plant to plan minimum control requirement in the commercial scale process

• Establish realistic energy efficiency figures

• Establish product quality through test marketing.

• Develop high confidence on product and process before making large investment

USEFUL LINKS FOR OTHER PILOT PLANT DESIGN AND PILOT PLANT SCALE UP :

Pilot Plant Design and Pilot Plant Scale-Up: Reduce Risk and Optimize Efficiency

Pilot plant design and pilot plant scale-up are critical steps in chemical and process engineering, enabling companies to mitigate risks and ensure success before committing to full-scale commercial production. At CHEMICAL PROCESS ENGINEERS, we specialize in designing and scaling up pilot plants, helping you refine your process and product while minimizing investment risks.

Why Invest in a Pilot Plant Design?

A well-designed pilot plant acts as a proof-of-concept for your production process. It allows you to:

- Test the technology on a smaller scale with reduced investment.

- Identify and resolve uncertainties related to product yield, quality, process losses, and utility requirements.

- Optimize production processes and equipment to minimize costs and maximize efficiency.

Pilot plant design is not just about scaling down a commercial process—it’s about validating the process, fine-tuning operations, and building confidence in the technology and product before large-scale investment.

The Role of Pilot Plant Scale-Up in Commercial Production

The pilot plant scale-up process bridges the gap between small-scale validation and full-scale production. This step provides invaluable insights that guide the design and development of a commercial production plant. Key benefits include:

- Process Optimization: Establishing the ideal operating conditions and minimizing batch times for efficient production.

- Equipment Selection: Identifying the right type of equipment for processes like filtration, mixing, reaction, evaporation, and drying.

- Cost Efficiency: Reducing production costs through process improvements and energy optimization.

- Product Validation: Confirming product quality and acceptance through test marketing.

Advantages of a Pilot Plant Design and Scale-Up Approach

- Risk Reduction: Minimize financial risks by validating processes at a smaller scale before large-scale investment.

- Process Balancing: Ensure seamless integration and utilization of multiple unit processes and operations.

- Equipment Optimization: Select and configure the best equipment to achieve precise results and efficient operations.

- Energy Efficiency: Establish realistic energy consumption figures to lower operational costs.

- Process Control: Develop process control logic to streamline operations in the commercial plant.

- Customer Validation: Use the pilot plant to test-market products and gather customer feedback.

How We Design and Scale Up Pilot Plants

At CHEMICAL PROCESS ENGINEERS, our pilot plant design and scale-up approach follows a structured methodology:

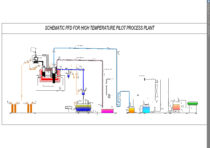

- Mass Balance and Energy Balance: We establish theoretical mass and energy balances to set benchmarks for process efficiency and production capacity.

- Data Collection: During pilot plant operation, we collect essential data on process parameters, product quality, and utility requirements.

- Process Engineering: We translate pilot plant findings into a detailed process design for commercial-scale production.

- Detailed Engineering: Using advanced tools like AUTOCAD (2D and 3D), we develop comprehensive equipment layouts and piping designs to ensure seamless scale-up.

- Continuous Optimization: We tweak production processes to achieve maximum capacity utilization and minimize downtime.

Build Confidence Before Large-Scale Investment

Our pilot plant design and scale-up services give you the confidence to move forward with your commercial production plans. By addressing potential issues during the pilot stage, you can make informed decisions, reduce costs, and achieve a higher return on investment.

Why Choose CHEMICAL PROCESS ENGINEERS?

- Experience: Over 35 years of expertise in process engineering, design, and scale-up.

- Customer-Centric Approach: We work closely with clients to deliver tailored solutions for their unique challenges.

Proven Results: Our pilot plant designs have helped clients optimize processes, validate products, and achieve successful commercial production.