About Us

WE DELIVER INNOVATIVE, EFFICIENT & VALUE-DRIVEN SOLUTIONS FOR CUSTOMERS ALL OVER THE GLOBE.

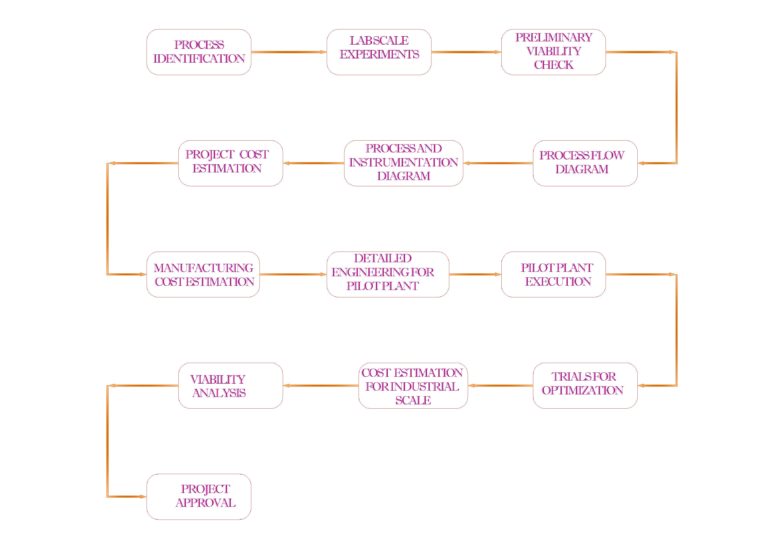

CHEMICAL PROCESS ENGINEERS specializes in scaling up processes from laboratory / bench-scale / pilot-scale to industrial / commercial production facilities.

CHEMICAL PROCESS ENGINEERS is a Process Engineering Firm catering to the needs of Process and Chemical Industry in areas of design, development, detailed engineering and trouble-shooting.

Since its inception in 1988, CHEMICAL PROCESS ENGINEERS have been assisting the process industry in small, medium and large scale to build up in-house expertise in process,equipment and project development, modernisation, scaling-up, project execution and trouble shooting.

Short term assignments, successfully carried out to trouble-shoot specific areas in existing plants have resulted in long term association with most of our Clients.

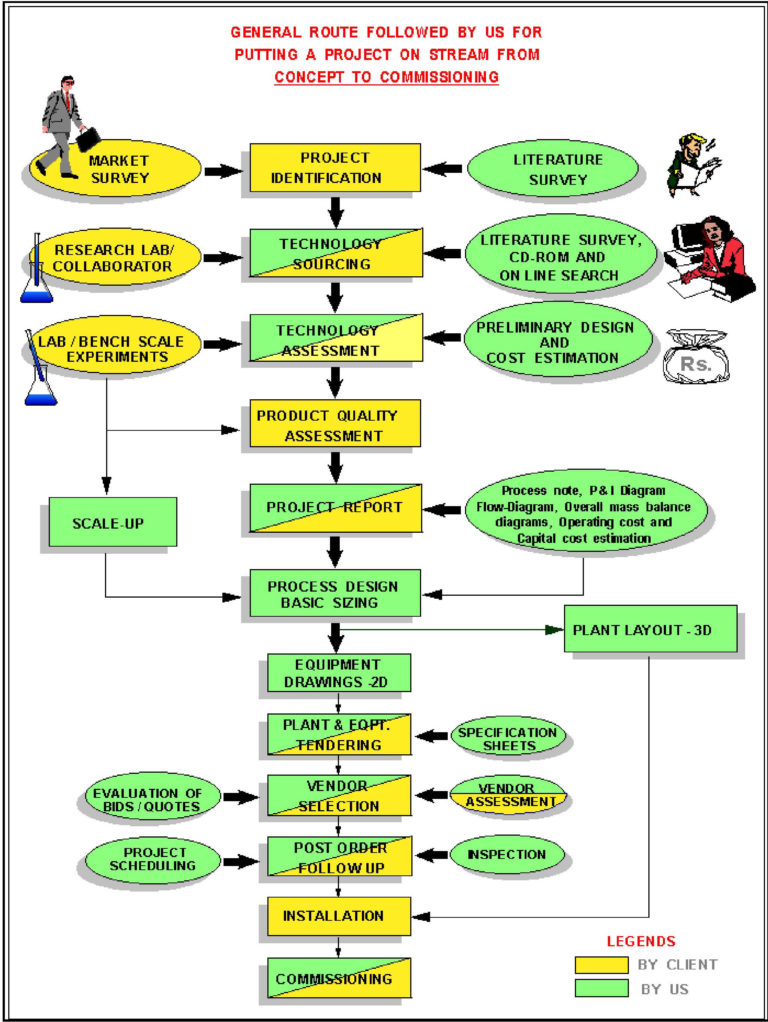

Ability to scale-up processes from laboratory or pilot scale to industrial / commercial level has been our basic strength. To ensure smooth implementation of such scale-up, we provide back-up services including R & D management, planning & designing of experiments, literature/document

survey, cost-benefit analysis and detailed engineering. This is pictorially depicted in the enclosed block diagram.

The first principle which Chemical Process Engineers follows for any process design is to establish a hypothetical mass balance and energy balance for the process. Hypothetical computation results in estimation of theoretically possible maximum production and minimum energy requirement for the process.

Mass balance and Energy balance thus established sets the bench mark for comparing results actually arrived in actual process, be it a pilot plant or pilot plant design and pilot plant scale up or a production plant.

Figures on maximum production established in mass balance and energy balance diagram is based on stoichiometry-based calculation.

Process engineering and detailed engineering activities carried out by us are adequately backed up by drawings on AUTOCAD 2-D and 3-D which helps in ensuring that equipments are manufactured in compliance with process design, with equipment layout and piping being carried out according to our design and site conditions. A few sample drawings prepared by us are

enclosed herewith for your perusal.

The undersigned is a Chemical Engineering graduate from the Indian Institute of Technology,Kharagpur (1976, B.Tech.- First Class) and has been in the field of Design, Development and Project execution for over thirty five years.

Mechanical Engineering activities including AUTOCAD work are looked after by Mr.Balaji and Mr.Ganesh while Chemical Engineers Mrs.Surekha & B.V.Darshan provide the process design support.

Our Clients interface with us at all stages of project execution to ensure seamless implementation of our basic and detailed engineering

Though we restrict our role to that of a Consultant, we share the responsibility of achieving targeted results through careful planning, that enables the management to take effective decision and achieve desired objectives.

AMITAVA BANERJI

COMPANY HISTORY

OUR MISSION

Our Team

AMITAVA BANERJI

AMITAVA BANERJI has been in the field of design and development for the lastthirty years and has successfully implemented the practice and principles of Chemical and Process Engineering since 1988 when CHEMICAL PROCESS ENGINEERS was conceptualised and set up by LATE NEELAM BANERJI a Chemical Engineer from BHU-IT and AMITAVA BANERJI. He is a first class graduate in Chemical Engineering from the IIT Kharagpur (1976 – B.Tech).

BALAJI L.S

BALAJI L.S, our Senior Mechanical Engineer takes care of most of the critical detailed engineering activities in our assignments. His quick grasp of `process’helps in coming up with practically implementable engineering solutions that are cost effective and result oriented. BALAJI L.S has been with CHEMICAL PROCESS ENGINEERS since 1998, a year after his graduation from SMVIT under Bangalore University.

DARSHAN B.V

SUREKHAN BE -Chemical Engineering, has been working in areas of basic and detailed engineering of various projects which are assigned to us by our clients. SUREKHA has graduated from MVJ College of Engineering under Bangalore University in 2000 and worked with Shriram Institute Of Industrial Research, Bangalore before joining us in 2010.

DARSHAN B.V

DARSHAN B.V is a post graduate in Chemical Engineering and has been, since 2012, contributing to the organic and inorganic chemistry relateddesign and scale-up activities that CHEMICAL PROCESS ENGINEERS deliver to their clients. DARSHAN B.V has his ME degree (2011) from Indian Institute of Science, Bangalore.

Expertise in Mass Balance and Energy Balance for Process Engineering

At CHEMICAL PROCESS ENGINEERS, we specialize in delivering innovative, efficient, and value-driven solutions to clients worldwide. Our expertise lies in scaling up processes from laboratory, bench-scale, or pilot-scale levels to industrial and commercial production facilities. With a strong focus on mass balance and energy balance, we provide cutting-edge solutions tailored to meet the unique needs of the process and chemical industries.

Who We Are: A Trusted Partner in Process Engineering

Since our establishment in 1988, CHEMICAL PROCESS ENGINEERS has been a reliable partner to small, medium, and large-scale industries. Our services span process design, development, detailed engineering, troubleshooting, and modernization. Over the years, we’ve built lasting relationships with clients through successful project execution and innovative problem-solving.

Our ability to scale up processes seamlessly from pilot to industrial scale is backed by robust services, including:

- R&D management

- Experiment planning and design

- Literature and document surveys

- Cost-benefit analysis

- Detailed engineering support

The Role of Mass Balance and Energy Balance in Process Design

For any process design, the first principle we follow is establishing a mass balance and energy balance. These calculations form the foundation for efficient and sustainable process engineering. Here’s how we utilize these balances:

- Mass Balance: This involves stoichiometry-based calculations to estimate the maximum theoretical production output. It helps identify raw material requirements, waste generation, and efficiency benchmarks.

- Energy Balance: By calculating the minimum energy requirements, we can optimize the energy usage for processes, ensuring cost-effectiveness and sustainability.

These balances serve as benchmarks, enabling us to compare theoretical estimates with actual results achieved in pilot plants, scale-up processes, or full-scale production facilities. This iterative approach ensures that processes are optimized for maximum production and energy efficiency.

Applications of Mass and Energy Balances in Engineering Projects

- Pilot Plant Design and Scale-Up: Using mass and energy balances, we develop accurate pilot plant designs, ensuring a smooth transition to industrial production.

- Process Optimization: Balances are used to identify bottlenecks and inefficiencies, helping us recommend process improvements.

- Detailed Engineering: Mass and energy balance data are incorporated into 2D and 3D AUTOCAD drawings for precise equipment and piping layouts.

- Cost Analysis: Energy balance calculations enable detailed cost-benefit analyses, helping clients make informed decisions about investments.

Advanced Tools and Expertise

Our process and detailed engineering activities are supported by state-of-the-art tools like AUTOCAD (2D and 3D). These tools ensure that equipment designs comply with process requirements and align with site conditions. Our experienced team includes:

- Chemical Engineers: Mrs. Surekha and Mr. B.V. Darshan, who specialize in process design.

- Mechanical Engineers: Mr. Balaji and Mr. Ganesh, who oversee mechanical design and AUTOCAD drawings.

The team is led by a Chemical Engineering graduate from the prestigious Indian Institute of Technology, Kharagpur, with over 35 years of experience in design, development, and project execution.

Why Choose CHEMICAL PROCESS ENGINEERS?

- Proven Expertise: Decades of experience in scaling up processes and troubleshooting industrial challenges.

- Customer-Centric Approach: We collaborate closely with clients at all stages of project execution, ensuring seamless implementation.

- Innovative Solutions: Our mass balance and energy balance techniques drive efficiency and sustainability in every project.

- Reliable Deliverables: From process design to equipment layout, every aspect of our work is meticulously planned and executed.

Let Us Help You Achieve Your Goals

At CHEMICAL PROCESS ENGINEERS, we don’t just offer consultancy services—we take responsibility for delivering results. Through careful planning and precise execution, we empower our clients to achieve their objectives with confidence. Whether you’re looking to scale up production, optimize energy use, or modernize existing processes, our expertise in mass balance and energy balance ensures your success.

Contact us today to discuss how we can help you design and execute efficient, innovative, and cost-effective process solutions