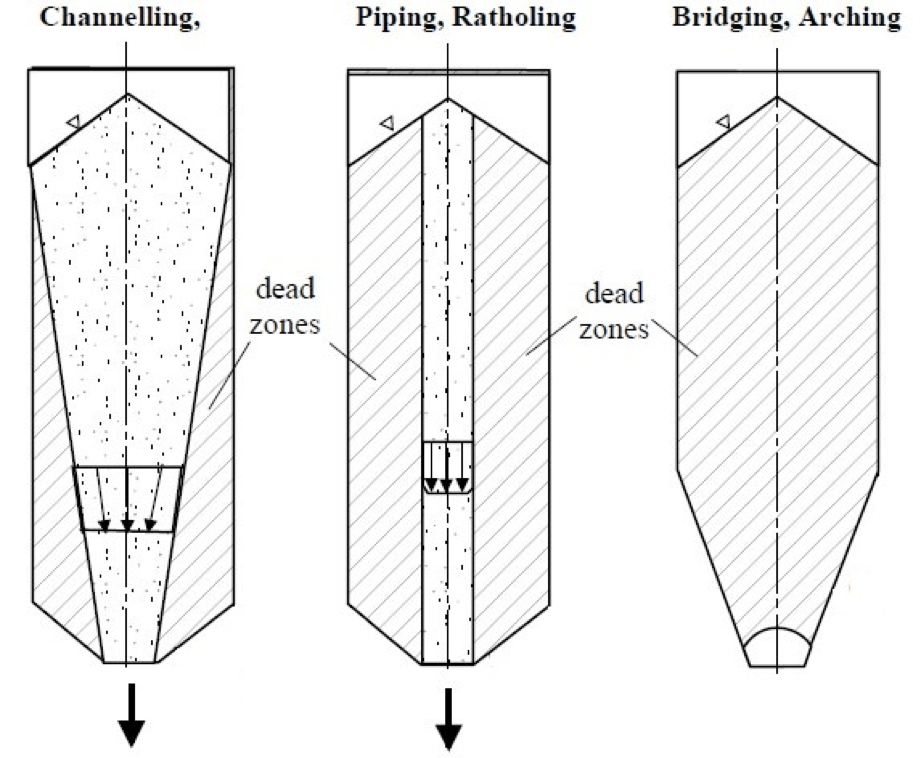

Following are the main material flow patterns and problems routinely encountered by the industries in a storage hopper. The flow patterns are illustrated in the figures given below and measures to fix them with Mass Flow Hopper.

Funnel Flow: The material starts flowing from the top surface in a conical fashion representing a funnel shape and the material near the wall is stagnant. This results in a first in last out flow pattern and can also result in material segregation problems.

Core or Ratholing Flow: The material starts flowing from the top surface in the form of a cylinder at the central portion of the hopper and all the material surrounding this central hole upto the wall is stagnant. This results in a first in last out flow pattern and can also result in material segregation problems.

Bridging or Arching Flow: The material does not flow at all and forms a stable arch just above the hopper discharge. Arching may be due to the mechanical interlocking of large particles or cohesive locking of fine particles due to factors like humidity, temperature, pressure etc,.

Operators generally overcome the above problems by using sledge hammers, poking of the material using rods either from the bottom or from the holes made on the sides of the wall, use external mechanical vibrators, provide internal pneumatic lines etc., to make the powder flow. All the above methods employed are temporary solutions and further leads to other type of problems.

Mass Flow: The best solution for the above material flow problems is a mass flow pattern, where at any instant of time, all the solid particles are flowing vertically downwards towards the outlet of the hopper. This will ensure that there is no stagnation of the material inside the hopper. Mass flow ensures that the material which first filled the hopper is the first to go out of the hopper. To achieve this, the hopper walls must be sufficiently steep and smooth to reduce the friction. Check hot air dryer design for more information.

Mass Flow Hopper: To design a mass flow hoppers, the properties of the powder must be generated in a shear cell tester. Typical results of the powder tests for mass flow hopper are given below.

Bulk Density & Tap Density Graph

Effective Angle of Wall Friction Graph

Effective Angle of Internal Friction Graph

Mass flow Hoppers Function Graph

Flow Function Graph

Critical Arching Diameter

Critical Rathole Diameter