DESIGN OF LOW TEMPERATURE PROCESSES

BEST QUALITY PRODUCT AT MINIMUM COST IS PRODUCED IN A PLANT THAT IS DESIGNED AND BUILT AROUND THE PROCESS

LET THE PROCESS DECIDE THE PLANT RATHER THAN THE PLANT DECIDING THE PROCESS

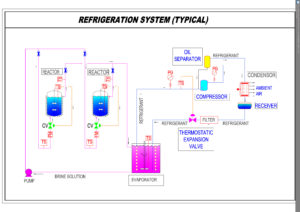

ChemiProcess designs,optimizes, details and helps the client execute systems or subsystems involving low temperature applications like low temperature chemical reactions, de-waxing of floral extracts, chilled air supply systems, etc.

DESIGN & ENGINEERING ACTIVITIES INCLUDE

- P & I Diagrams

- Estimation of chilling loads under steady-state & un-steady state or transient phase of the process

- Extraction of exothermic heat of reaction at sub-normal temperatures down to MINUS 35 oC where cooling water temperatures are not adequate

- Mass balance diagrams

- Energy balance diagrams

OPTIMISED DESIGN OF REFRIGERATION SYSTEM HELPS TO BRING DOWN ENERGY COST AND INVESTMENT

- Design capability available with ChemiProcess helps evaluation of bought out brine chilling plants

- Design & detailed engineering service provided by ChemiProcesshelps the client in sourcing the right components like compressors, condensing units, thermostatic expansion valves, condensers, brine circulation tanks, control system, etc. to help build up chilling systems for integration with the heat producing loads like reactors, condensers, etc.